Recently, a client of mine expressed their disappointment with a planning implementation. I would be remiss not to mention that another consulting firm had implemented this disappointing solution. Regardless, the issues as described were that users did not trust the data, and the granularity of that data was insufficient for a some of its business. I would say these are fairly common grievances.

Granularity: very typical. Either a miss in project requirements or users trying to do more than what the system was intended to do. If the project requirements were off, then shame on the client. If the users’ expectations were too great, it could be readily resolved with improved Change Management.

Data mistrust is a different matter. I could be data quality or the overall data strategy is poor. Yet, after review, it turned out to not be a data issue whatsoever. The root cause was a gap in the company’s planning solution. They lacked an Operational Plan in the 0-3 month horizon. It’s not their fault entirely, because a good system integrator would never have moved forward with the implementation as it was proposed. But let me give you the background in how a situation like this can develop.

Several years ago, a consulting firm was brought in to implement best practice processes around S&OP, which it did. The processes were sound, and with the usual best practice of focusing S&OP in the Tactical (4-24 month) plan. That is the time horizon during which leadership can truly make value-adding decisions. Then they brought in a system integrator to implement a best-in-class planning solution. And, while I would criticize this integrator for not doing enough due diligence around the proper planning level, the implemented solution matched up well with the process that had been defined. So if both groups did a reasonable job, then why was the client so disappointed?

Because they were only focusing on solving the Tactical plan questions and had no process or solution for the Operational plan. There were local spreadsheets being used for the Operational plan; however, there was no means of consolidating these plans and including them in the Tactical planning solution. They had a gap in their planning horizon.

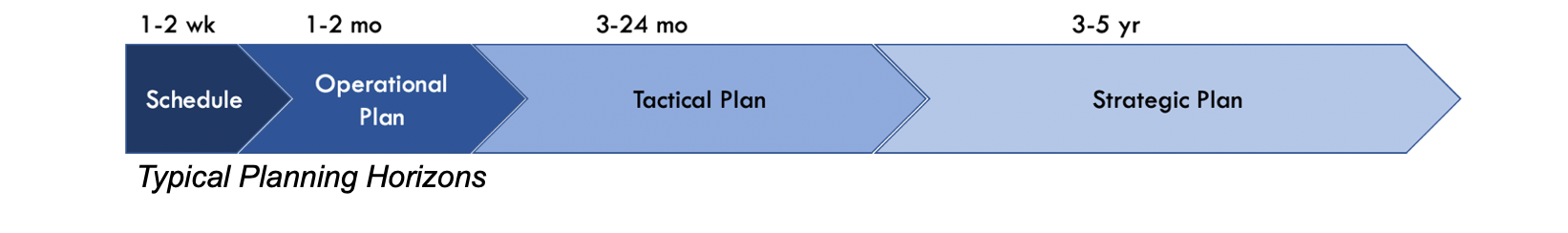

One of the biggest sins that I see in planning solutions is having a gap in the overall planning horizon. All businesses have multiple plans across the planning horizon, and if done well, each plan builds upon the previous one. The challenge is each plan is trying to answer different questions, thus the detail and model needed for each plan is different. No one-size-fits-all here, but typically these plans are (from left to right):

• Schedule - typically 1-2 week: Hourly or Daily buckets to provide an optimal, operational schedule. Tells the factory floor what to make and when. Cost to change is extremely high, and this schedule is normally “locked” for a period.

• Deployment plan (not shown above)- typically 1-2 week, maybe longer depending on transport arrange time. The two goals are: 1) distribute product scheduled for production (move product from the manufacturing site if storage is not available), and 2) replenishment of the distribution network (ensuring you have the right product at the right place).

• Operational plan- typically 1-2 months: Daily or Weekly buckets. Aligning supply to demand with an emphasis on operational efficiency. Usually involves campaigning/grouping of products to minimize changeovers. Provides visibility to manpower gaps that may take several weeks to bridge. Cost to change is moderate in this horizon and usually involved expedited shipments or overtime. Note: The first 2 weeks are inherited from the Schedule or Deployment plan.

• Tactical plan- typically 3-24 month horizon: Weekly or Monthly buckets. Aligning supply to demand with Rough-Cut Capacity Plan (RCCP) to enable S&OP level decisions. This is the wheelhouse of S&OP/IBP forums. It’s where the Cost to change is low, but the value contribution is high. Best with aggregated data to simplify the decisions that need to be made. Note: The first 2 months are inherited from the Operational plan.

• Strategic plan- 2-5 years: Yearly buckets. Goal is to align Capital Investment planning to future needs. Typically tied to critical assets. Note: The first 2 years are inherited from the Tactical plan.

Now, every business is different, and for some, these plans are irrelevant. For example, a distributor may not need a Schedule, but likely would need a Deployment plan. The plans that most industries require are Operational & Tactical. Ignoring either of these will likely lead to frustration within your organization. Lacking an Operational plan results in an overall lack of confidence in what is happening today. Lacking a Tactical plan results in a very reactive organization. Scheduling and Deployment are very localized and short-term, thus their impact on a Tactical plan is minimal. Strategic plans are typically performed in spreadsheets and assembled annually, but they are only slightly reliant on Tactical plans and not at all reliant on Operational plans.

So why are we bothering with the elementary school lesson on planning horizons?

Because if you have a desire to implement a technology solution, you need to ensure the entire planning horizon is covered in some form or fashion. And, if you have gaps, then you need to address them in a logical order. Otherwise, you’re building a house of cards. For example, you need to have an Operational plan before you work your way out to Tactical and Strategic planning. Implementing a Tactical planning solution without an Operational planning solution will fail. Ultimately, you will end up with planning results that lack credibility. It’s the proverbial cart-before-the-horse scenario.

Similarly, if you are going to implement a detailed Operational planning solution without Deployment, you’d better know what you are getting into. I’ve seen many organizations frustrated by a gap in the planning solution at a detailed level. Think the entire solution through and begin the process from left to right.

If you find yourself troubled with your current planning process or systems, give me shout at rob.jones@bullwhipsolutions.com

#SupplyPlanning, #S&OP, #IBP